Atmospheric Pressure Chemical Vapour Deposition is a CVD method. A Basic CVD system can typically broken up into the following three components (1) precursor delivery; (2) the CVD reactor; and (3) exhaust management. As we explained in CVD article above.

Atmospheric Pressure Chemical Vapour Deposition is a CVD method at normal pressure (atmospheric pressure). Which is used for deposition of different oxides. An atmospheric pressure chemical vapor deposition (APCVD) system uses atmospheric pressure or 1 atm in the reaction chamber.

APCVD is compatible with vacuum free, continuous in-line processes, making it very attractive for cost sensitive, high volume manufacturing applications like PV cell manufacturing.

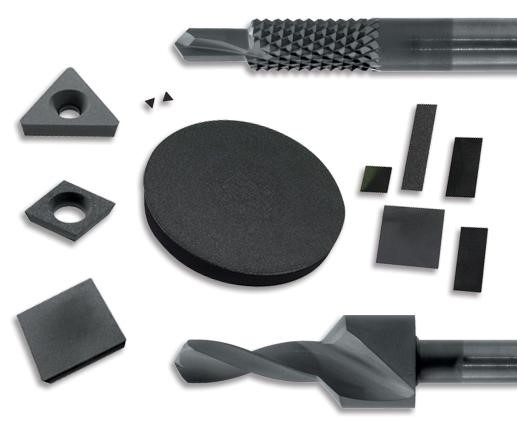

High Temperature APCVD process used to deposit epitaxial Si and compound films in cold wall reactor or hard metallurgical coatings like TiC and TiN in hot wall reactor.

Types of Reactors

In “cold wall reactor” only the substrates are heated by using a graphite susceptor. This is heated by RF induction. This minimizes deposition on the reactor walls since only the susceptor and substrates are hot. Large temperature near the substrate can impact gas flow and cause non-uniform depositions (in terms of thickness and micro structure). Therefore in these systems more care and attention must be given to gas flow dynamics.

In “hot wall reactors”, the substrate and the reactor wall are at comparable temperatures. Deposition also takes place on the walls, which can cause powders and also flakes to break off and fall onto the substrate. Homogeneous vapor phase reactions are also common in this type of reactor. However, these types of reactors lend themselves well to batch processing and are rather simple to implement.

Low Temperature APCVD process is used to deposit many insulating film layers like Sio2 and also BPSG glasses. The deposited oxide has a low density and the coverage is moderate due to a relatively low temperature.

Applications:

APCVD has been used for many films, especially epitaxial silicon deposition and silicon dioxide both undoped and doped with boron and phosphorus.

It can also used to produce compound semiconductors, SiO2, anti reflection (AR) coatings for eyeglasses and camera lenses, and transparent conductive oxide (TCO) coatings.

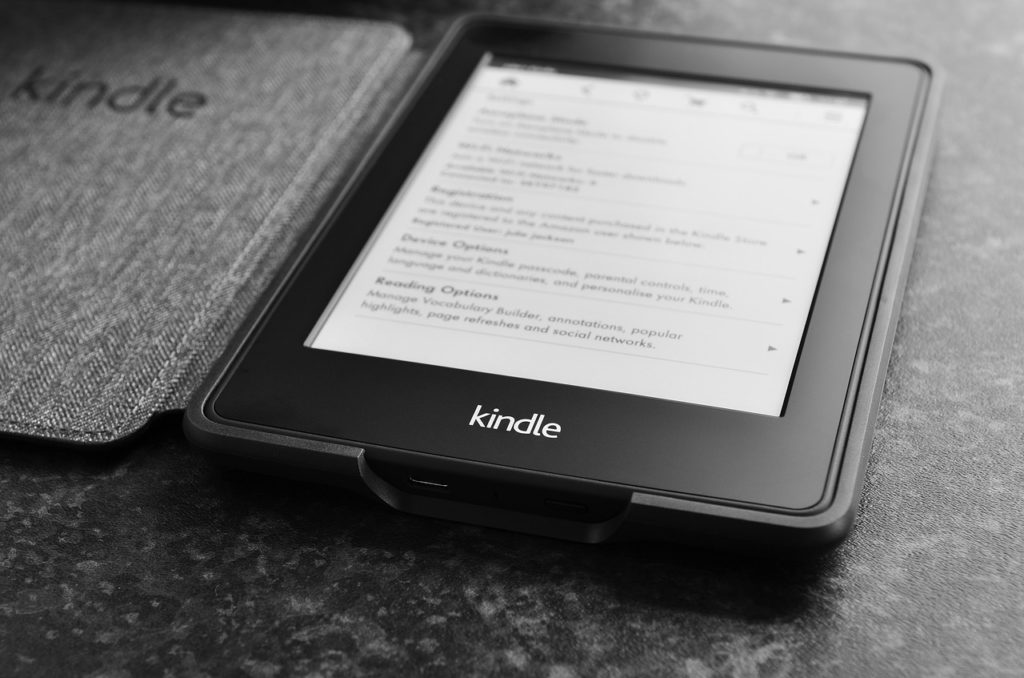

Transparent conductive oxides are transparent and electrically conductive. Therefore these are used for making flat panel displays like LCD, OLEDs, touch screens and solar cells

APCVD is also used as a surface finishing process for items such as tools and turbine blades to improve lifetime and performance.

High temperature APCVD process to produce thin films are recognized by many technologies such as given below

solid-state electronic devices

high quality epitaxial semiconductor films for silicon bipolar transistors

metal oxide semiconductor (MOS) transistors

optoelectronics and energy harvesting

Graphene-based devices for applications in flexible electronics

Graphene is transparent, conductive and also flexible. It is used for making Solar cells, LED’s, touch panels and smartphone displays.

Graphene has outstanding conductivity, mechanical strength and also thermal stability. which has made it very special material. There are various graphene production methods but atmosphere pressure chemical vapor deposition (APCVD) is one of the best. This is because of its very low diffusivity coefficient. Which is critical requirement for graphene production.

For more articles in Vacuum Technology please subscribe